You've heard the claims about stonegrinding - "Make old skis fast and new skis faster!" Sounds like a fad diet for your skis doesn't it? Lets explore these claims and hopefully provide enough information about stonegrinding that you can decide for yourself if this is something your old or new skis need.

Before we do that, a little review of the basics...

What affects ski glide and how do you make ski bases glide faster?

Ski Base Flatness

Lack of ski base flatness can be caused by wear, poor scraping, warping due to overheating and often is due to the manufacturing process and existed when the skis were purchased.

Ski Base Smoothness

Fine hair can be caused by sanding, wire brushing or polishing with fibertex pads. Lack of smoothness can also be caused by scraping a base that has become hard through overheating, or by inexperienced steel scraping. Careful grinding will recondition and smooth the base.Ski Base Structure

"Structure" refers to small grooves or lines that are put into the base. These grooves relieve the adhesion caused by the presence of water in the snow. The structure may be created by stone grinding or hand rilling and range from simple parallel lines to complex crossing patterns.

Ski Base Wax Absorption

“Wax absorption” is affected by the condition of the base surface. The surface layer of a ski base can be melted by an iron that is too hot thus sealing the base and not allowing wax to penetrate. Also excessive use of extremely cold wax and high fluoro wax can also seal ski bases. This is a very common problem, and you may not even know it has occurred.

New skis frequently suffer from bases partly melted during factory grinding because the stone isn't properly maintained or the manufacturer uses grinding as a quick flattening technique, taking off too much base each pass. All this results in rapid wax wear and the familiar gray spots along the base. Periodically the top most layer of base material has to be removed to open up the bases and allow wax absorption.

Stone grinding is the best method of dealing with all these problems. Stone grinding adds a structure that is suited to your prevailing snow conditions.

Structure: Rilling or Stone Grinding

Rilling is a process of pressing a temporary structure into the base, usually with a metal bar or rilling 'tractor' tool. A tractor tool helps guide the bar or cylinder down the ski length ensuring parallel lines. These tools can be quite expensive, often thousands of dollars for those that offer several structure options. Rilled structure is temporary and will disappear after a few waxings. This can be advantageous in some circumstances.

Stone grinding is the process of flattening, polishing, structuring and cleaning a ski base in order to make skis glide faster. The use of stone grinding techniques will result in a flat base with a fresh, open p-tex base surface for good wax absorption, and a permanently structured base suited to the snow conditions.

The final structure is actually pressed into the ski by the stone. In order for a stonegrinder to evenly press a final structure into a ski, it must be extremely flat. How flat? If the final structure is only 0.01mm deep, then the ski must be flat across the entire width without bumps or dips greater than that depth, otherwise part of the ski will not make contact with the stone as the base passes over it and that section of base will be left without structure. So, before a ski is ever put through a stone grinder a technician will do a careful assessment of the ski for flatness. Defects, scratches and other flatness problems (high/low spots, rounded edges, sealed patches, etc..) will require some manual work either with a metal scraper or sanding block to make it possible to run them through the machine and get good results. Don't expect to take badly abused and deeply gauged rock ski bases to a stone grinder and get them back perfectly flat, smooth and new again. There's only so much base material there to work with. But new or old skis with a few scratches or nics can usually be made flat and smooth for grinding.

It's also common misconception that stone grinding removes a lot of base material. Belt sanders found in most downhill and some xc shops can be used to remove a lot of base material, but a stone grinder doesn't. On each pass, the stone is only capable of removing about 0.1mm at a time. Attempting to remove too much base material per pass can cause waves along the ski length or in sealed sections of base as the stone is likely to overheat.

To ready the ski for the final structure it may be run through the grinder several times until the technician is satisfied that it is evenly flat and smooth and ready for the final structuring. This structuring might involve a single pass, or multiple passes through the grinder to layer structure in order to achieve the complex patterns required to deal with the snow conditions the structure must solve.

What Structure is right for your skis?

The structure of your ski base is crucial in determining what snow conditions your skis will best glide in. Keep in mind that ski camber is the biggest factor in determining if a ski is suited to the snow conditions. You can't put a cold, dry snow structure on a wet snow ski and get great glide in cold, dry conditions. Make sure you know the camber characteristics of your skis before picking the structure for them. You might want to read Karl's tips on selecting a complete fleet of skis and Andrew's notes on dealing with the gaps in your fleet.

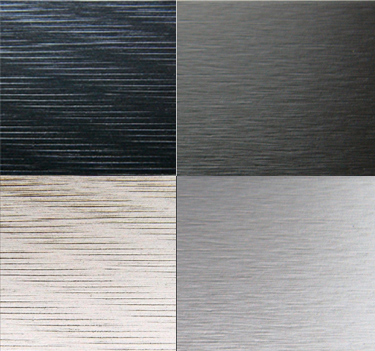

There are some general rules for structure. For cold, dry snow a fine, shallow, smooth structure that the sharp snow crystals won't grab is best. For warm, wet snow, a deeper more aggressive, often a broken "V" structure helps break up the suction caused by excess moisture in the snow. See the differences in the pictures below.

This is a side-by-side comparison of [Left] a typical factory grind (for very humid snow) and [Right] a grind better suited to Ottawa's cold dry snow. The bottom images are negatives of the top in order to better see the structure. Click on any square for a closer look.

Just like waxing, temperature isn't the big factor you worry about when choosing a structure - it's snow type and moisture content that are important! Ottawa typically has dry, old snow...this year we saw more moist and new snow, but that was exceptional.

Now, you can get as specific as you want with the grind you select but that will narrow the conditions in which the skis work well. I usually try to get 'general purpose' cold grinds on skis well suited for hard and soft conditions. I'll usually use these skis from -20C to 0C. Then I'll have wet snow skis with more exotic aggressive grinds. If you have more than one pair you can choose different structures to match the conditions best suited to those skis.

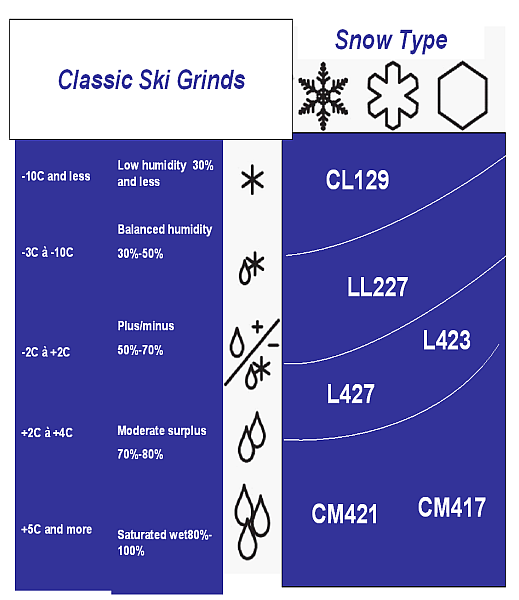

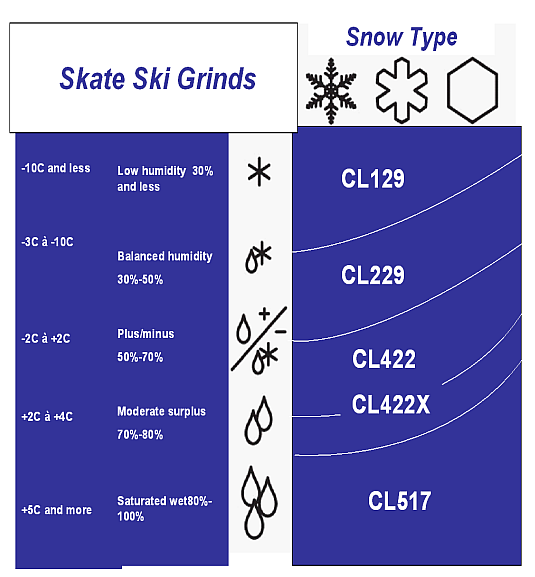

You might find that information where its suggested that you structure skating skis and classic skis differently for the same conditions. This advice might sound strange at first, but classic skis that glide mostly in the tracks and skating skis that glide mostly out of the tracks have different needs. Generally you want your classic skis ground to be useful in a larger range of conditions so that you can take advantage of the wax pocket characteristics in more situations. Skatings skis on the other hand often face tougher conditions, so you might want to narrow your grind selection and designate a pair of skis for specific conditions. This is good advice for people with a big bag of skis, but if you have to choose just one stay drier and colder and add hand structure if need be.

Phew, that's a lot to digest. If you've made it this far, congratulations and I hope you found this useful. So have you decided to grind or not? If you do decide to have your skis ground, then there are only a few more things you need to know ...

Where Should I Get My Skis Ground?

Not all stonegrinding will result in a flat base and faster skis - it takes an experienced technician who understands the mechanical factors (ski pressure, stone speed, thermal effects, etc..) that need to be controlled for each grind. Stone grinding machines need constant care and upkeep to produce quality structure - stones must be constantly maintained or 're-dressed'. Stone grinding isn't rocket science, but it is highly technical and does require trained technician with experience and expertise to produce grinds that will make skis faster. This isn't something a high school kid working in the back of a ski shop for minimum wage is qualified to do. A poor stone grinding job may actually damage <

If you are interested in getting your skis stoneground I would suggest you contact RGS (Racing Grind Service) at 418-831-6482. They are located in Quebec City and are the closest shop with the right experience; 15 years of surface conditioning expertise with bonded abrasives (grinding stones and otherwise). They collaborate with World Cup level wax and stone grinding specialists to offer a full menu of grinds for all conditions. RGS will work on skis all year round which is nice because you really don't need them in the summer and you can ship them off in the spring get them back all ready for next season.

Check out their grind menus below. This winter I tested their CL129 and CL229 grinds and had great success with both grinds. I think either functions really well as a general purpose Ottawa grind.

If you have questions about anything in the article you can conduct us or RGS to discuss it further.